Bed: The overall box-type slant bed is used to achieve excellent stability and high rigidity. The bed uses finite element analysis (FEM) to optimize the design of the ribs inside the integrated bed. The strength of the bed is 30% higher than the traditional design, and the heat flow balance design can meet the long-term processing requirements. The bed is cast from high-strength cast iron and resin to provide sufficient rigidity, strength and stability for the bed. The guide rails are all rectangular hard rail structure, with large bearing capacity, good anti-vibration performance, improved machine tool characteristics, improved machine tool accuracy and precision stability, and improved machine tool life.

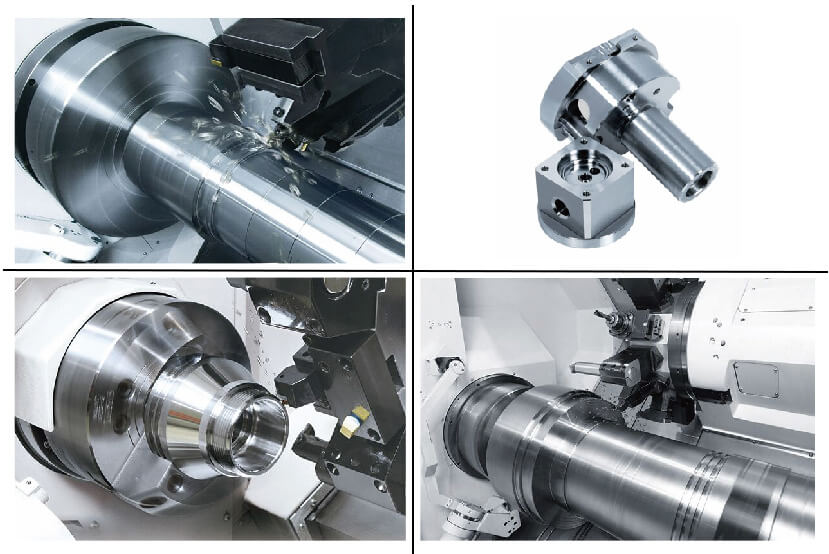

Spindle box: The spindle box incorporates the latest Japanese design technology. It adopts high-precision, high-speed, high-rigidity and independent single-spindle structure to match high-speed and high-torque spindle motors, which greatly improves production efficiency and achieves excellent machining results. The spindle bearing adopts imported bearings (NSK, etc.) and grease lubrication technology, which makes the spindle have high precision, high speed, high load and low temperature rise. It can not only withstand large power and high torque cutting, but also has high spindle precision and life. .

Knife tower: HST series ultra-fast horizontal hydraulic servo turret adopts the latest design products, technology, manufacturing, testing and other key aspects of the latest products. 1) High rigidity: The optimized box installation structure fully guarantees the best position for the combination of the tool holder and the machine tool. The optimized end tooth plate tooth shape and large diameter end gear plate design combined with hydraulic locking ensure the maximum product. High rigidity, easy to handle both large cutting and high speed finishing. 2) High precision: The unique German high-precision CNC end gear grinding machine fully guarantees the repeat positioning accuracy of the turret, and it can still guarantee the stability of machining precision in large cutting. 3) High efficiency: The excellent combination of high-speed servo motor and high-precision reducer ensures the extremely high indexing speed of the tool post. It does not need to return to zero when the machine is powered on. It is the first choice for high efficiency. 4) Low energy consumption: low-power high-inertia servo motor with unique servo turret control technology has changed the high energy consumption and low efficiency of traditional electric and hydraulic tool holders, greatly reducing the power supply of the machine tool and the load of the hydraulic system. The cost of the user is saved.

Programmable tailstock/hydraulic tailstock: The tailstock is driven by servo control and hydraulically locked, which greatly saves the clamping time and automatic operation of the tailstock workpiece, improves the machining efficiency, and can be used for simple tool preparation.

| Project | RTC3550 | RTC3580 | |

| Processing capacity | Maximum swing diameter | Φ580mm | |

| Maximum swing diameter on the saddle | Φ350mm | ||

| Maximum machining diameter | Φ430mm | ||

| Maximum processing length | 500mm | 850mm | |

| Rod through the operating capacity | Φ75mm | ||

| Trip | X-axis stroke | 325mm | |

| Z-axis stroke | 600mm | 950mm | |

| Spindle | Spindle model/aperture | A2-8/Φ87 | |

| Card size | N210/A2-8 | ||

| Hydraulic swing cylinder | M1875/Φ75mm | ||

| Maximum speed | 2500rpm | ||

| Variable speed sins | Stepless speed regulation | ||

| Spindle nose form | Optional: A2-11/Diameter105mm | ||

| Knife Tower | Knife Tower Form | Servo turret | |

| Number of tools | 12 | ||

| Knife rod size | 25*25mm | ||

| Knife rod diameter | Φ50mm | ||

| Project | RTC3550 | RTC3580 | |

| Feed speed | X-axis fast-forward speed | 20000mm/min | |

| Z-axis fast-forward speed | 20000mm/min | ||

| Tails | Tail-seating itinerary | Φ430mm | |

| Tail-seater spindle cone hole | 400mm Servo programmable tailstock | 700mm 伺服可编程尾架 | |

| Motor | Spindle motor | 18.5kW | |

| Hydraulic pump motors | 1.5kW | ||

| Cooling pump motor | 1.5kW | ||

| Electric/gas/ hydraulic |

Power capacity | 35kVA | |

| Gas source | 0.5mpa(5kgf/cm2),150L/min | ||

| Hydraulic | 2.5-5Mpa | ||

| Cooling | Tank capacity | 150L | |

| size/weight | Machine height | 1970 | |

| Covers area | 2950(+1215 Cutting machine)*2115 | 3250(+1215 Cutting machine)*2115 | |

| Machine weight | 6000 | 6500 | |

| Machine accuracy | Repeat positioning accuracy (X/Z axis) | 0.006mm | |

| Positioning accuracy (X/Z axis) | 0.012mm | ||

● standard accessories ★ optional accessories

No.766, Zeguo Avenue, Zeguo Town, Wenling City, Zhejiang Province, China

Phone: +86-576-86422000

Mobile: +86-17681687681

1175936047@qq.com

Fax: +86-576-86403666